If you routinely request quotes for magazine printing and mailing uk (United Kingdom), you already know the headline number can mask a multitude of extras that surface only when your file is on press or your mailing list hits the sorter. From prepress fixes and paper substitutions to wrapping choices, address-data processing, and postage surcharges, the total landed cost of a campaign can climb by double digits without clear warning, undermining budgets, delaying schedules, and eroding returns for publishers, marketers, and production managers. Because small shifts in pagination, trim size, cover treatments, or mailpiece weight can recategorise your item for Royal Mail (Royal Mail Group Limited) and international carriers, a single gram or millimetre often flips your rate band and triggers unplanned spend. Drawing on more than three decades of end-to-end production, mailing fulfilment, and worldwide distribution, Cliffe Enterprise Limited explains the ten most common hidden charges, why they appear, and how to structure your specification, procurement, and approval process to prevent them while maintaining quality and on-time delivery.

What Typically Gets Missed in quotes for magazine printing and mailing uk (United Kingdom)

Magazine manufacturing and distribution is a chain of interdependent stages, and the cost of each stage is shaped by technical constraints that rarely fit on a single-line quote. Print-only prices often exclude prepress remediation, press make-ready, and finishing variances, while mailhouse estimates may leave out data hygiene, sortation, and returns handling. Meanwhile, postal bills can change if your item breaches machinability thresholds or weight bands set by Royal Mail (Royal Mail Group Limited), Downstream Access carriers, and international networks, especially when the design introduces high-bulk papers, heavy inks, or unusual formats. Without explicitly defined tolerances, test weights, and route assumptions, many suppliers price best case and charge the difference later.

International distribution introduces yet another layer of risk. EU (European Union) compliance regimes such as ICS2 (Import Control System 2) and customs data requirements elevate the importance of accurate HS (Harmonized System) codes, electronic advance data, and correct sender identifiers like EORI (Economic Operators Registration and Identification). If these elements are mishandled, consignments can be delayed, re-rated, or returned, adding cost and reputational damage. Cliffe Enterprise Limited provides IOSS-ready VAT handling and bespoke international logistics and clearance support for consumer titles into Europe, helping to optimise routings, documentation, and customs clearance to mitigate these pitfalls and limit transit delays and cost volatility for both small runs and bulk orders.

Ten Hidden Costs You Should Audit Before You Approve Any Quote

- Prepress Remediation and Colour Management. File preflighting, bleed fixes, font replacements, and RGB (Red Green Blue) to CMYK (Cyan Magenta Yellow Key) conversions are frequently excluded. Expect added fees for image resolution repair or unmanaged spot colours in PMS (Pantone Matching System). Practical tip: request a written preflight report, acceptable tolerances, and a capped rate for corrections.

- Paper Stock Substitutions and Price Volatility. Mill surcharges, FSC (Forest Stewardship Council) certification premiums, and unplanned substitutions can shift weight and bulk, affecting postage. Lock the gsm, caliper, brand, and reel width, and ask for a price-adjustment clause that shares risk above a defined index threshold.

- Press Make-ready, Plates, and Versioning. Setup time, extra plates for special inks, and short-run version switches often appear as job-cost extras. If you run multiple regional covers or inserts, specify version counts, plate changes, and washups to receive an all-in setup price rather than open-ended charges.

- Finishing Upgrades and Process Variance. PUR (Polyurethane Reactive) binding, spine milling, lamination, foiling, or spot UV (ultraviolet) are sometimes quoted as options but invoiced as necessities after materials are reviewed. Define mandatory finishes up front and include tolerances for trim, square-back, and crack-resistance on heavy inks to avoid late-stage upgrades.

- Waste, Overs, and Spoilage Allowances. Print and bind inevitably generate waste; mailhouses often require overs for setup. If your quote excludes overs, you may pay for additional copies later. State waste and overs as percentages with caps, and clarify ownership and use of overs post-mailing.

- Data Hygiene, Suppression, and Sortation. De-duplication, PAF (Postal Address File) validation, NCOA (National Change of Address) processing, and MPS (Mail Preference Service) suppression reduce undeliverables but are commonly unquoted. Ask for a line-by-line fee schedule per thousand records and evidence of GDPR (General Data Protection Regulation) compliant processing.

- Wrapping and Enclosing Choices. Poly wrap, paper wrapping, and envelope enclosing vary widely in material, machinability, and environmental performance. Bio-films and paper wraps may carry EPR (Extended Producer Responsibility) implications and density-driven postage changes. Compare material gauges, pack formats, and machine speeds to understand true cost per mailed copy.

- Postal Reclassification and Surcharges. Minor shifts in thickness, tabbing, or address placement can push items out of machinable categories. Missed mailpiece design rules lead to manual-handling surcharges and return fees. Request a machinability test and sample approval before bulk lodging to lock your rate card.

- International Compliance and Returns. Incorrect HS (Harmonized System) codes, missing tax identifiers, or non-compliant labeling drive rework, customs holds, and return-to-sender charges. For Europe, leverage a partner with proven IOSS-ready processes and bespoke international logistics to streamline documentation and reduce border friction.

- Project Management, Storage, and Split Deliveries. Staggered call-offs, palletisation specs, delivery time-windows, and regional drops are often priced after the fact. Ask for itemised charges for pick fees, storage per pallet per week, re-labelling, and timed deliveries to prevent avoidable accessorials.

| Hidden Cost Area | Typical Add-on | Notes |

|---|---|---|

| Prepress remediation | 0.5 to 2.0 percent | Complex colour fixes or template changes raise cost |

| Paper substitutions | 1.0 to 3.0 percent | Bulk shifts may affect postage |

| Make-ready and plates | 0.5 to 1.5 percent | Versioning and specials add plates |

| Finishing upgrades | 1.0 to 4.0 percent | Lamination or PUR (Polyurethane Reactive) binding |

| Waste and overs | 1.0 to 3.0 percent | Mailhouse setup and spoilage |

| Data hygiene and sortation | 0.5 to 1.5 percent | Depends on list health |

| Wrapping and enclosing | 1.0 to 5.0 percent | Material and speed trade-offs |

| Postal surcharges | 1.0 to 6.0 percent | Machinability and weight bands |

| International compliance | 1.0 to 4.0 percent | Documentation and returns |

| Project management and logistics | 0.5 to 2.0 percent | Split deliveries and timed drops |

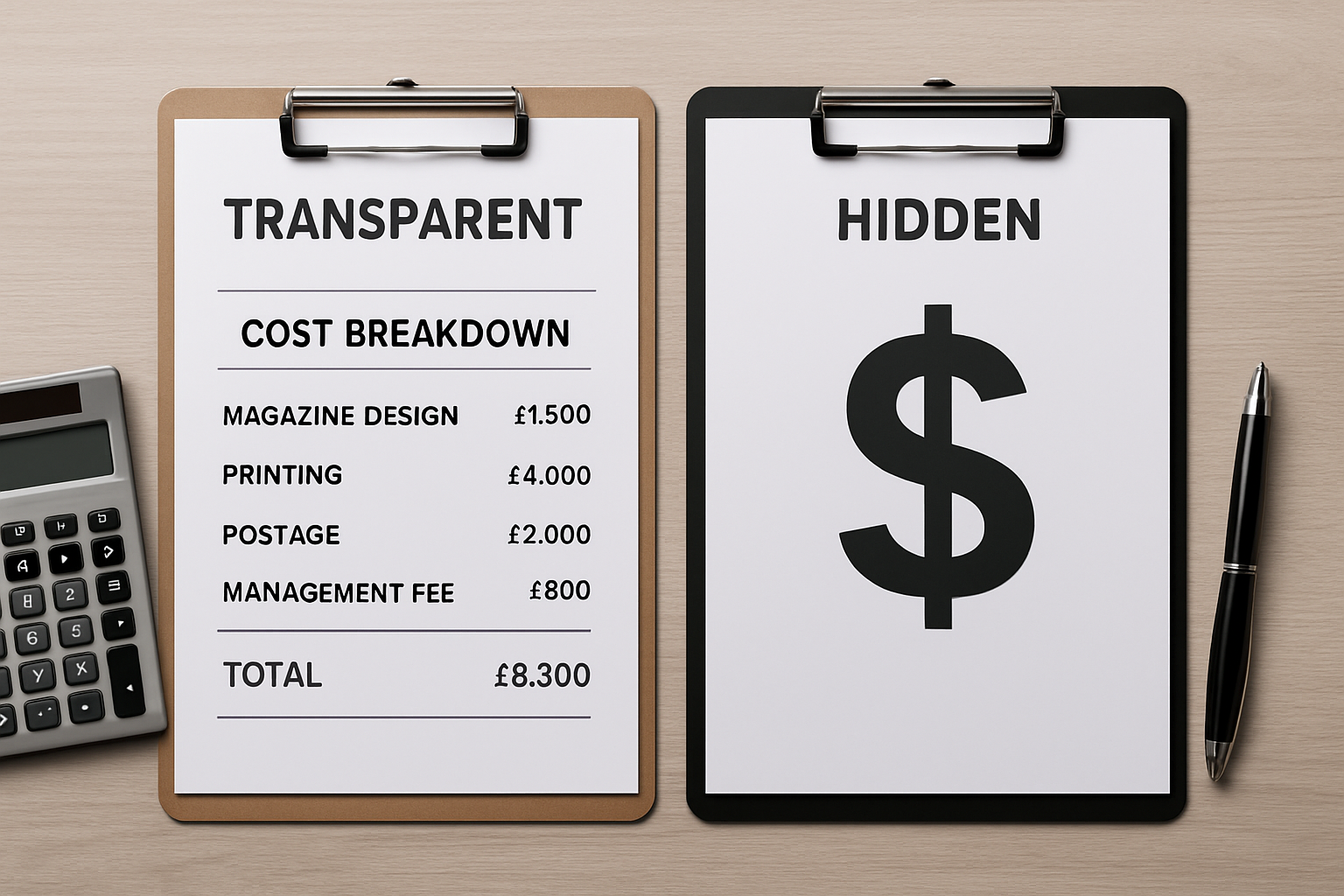

Cost Model: Transparent vs Hidden Quote on a Typical Campaign

Consider a 20,000-copy, 64-page consumer magazine with a heavier cover, mailed to UK (United Kingdom) subscribers and a European segment. The figures below are illustrative and vary by specification, market conditions, and postal rate cards, yet they show how seemingly small line items compound. Transparent quotes itemise every production and mailing input with documented assumptions and tolerances. Hidden-cost quotes present attractive unit prices, then recoup margin through surcharges and ex-post fees once schedules, materials, or data are locked.

| Cost Component | Transparent Quote | Hidden-Cost Quote | Comment |

|---|---|---|---|

| Print manufacturing | £21,400 | £20,600 | Lower headline price excludes make-ready and overs |

| Prepress remediation | £0 to £350 capped | £900 | RGB (Red Green Blue) images, bleed fixes |

| Make-ready and plates | Included | £650 | Added for regional versioning |

| Finishing upgrades | Included in spec | £1,100 | PUR (Polyurethane Reactive) binding upgrade after review |

| Wrapping/enclosing | £3,200 paper wrap | £2,400 poly wrap + £650 bio surcharge | Material choice and EPR (Extended Producer Responsibility) impact |

| Data processing | £480 | £920 | PAF (Postal Address File), NCOA (National Change of Address), MPS (Mail Preference Service) |

| UK (United Kingdom) postage | £12,600 | £13,900 | Weight band shift from paper swap adds surcharge |

| EU (European Union) postage | £7,300 via IOSS-ready routing and bespoke international logistics | £8,400 direct injection | Routing and customs-clearance support optimises documentation and reduces border friction |

| Returns handling | £0.06 per item as quoted | £0.12 per item ad hoc | Undeliverables double when data hygiene skipped |

| Project management and logistics | £680 | £1,150 | Split deliveries and timed drops charged later |

| Total estimated | £45,660 | £50,670 | Headline difference reverses after add-ons |

In industry audits, unquoted extras routinely add 8 to 15 percent to campaign spend, with postage, finishing variances, and data-processing omissions as the largest drivers. A transparent, postal-compliant plan that fixes materials, weight, and machinability up front while validating address data and international paperwork can reclaim a five-figure sum on a mid-sized mailing. Cliffe Enterprise Limited provides fully itemised estimates that include tested dummies, sample approvals, and route plans to lock rate cards before you commit print funds.

Postal Compliance and Distribution: Where Accuracy Protects Your Budget

Postal networks reward machinable, well-prepared items and penalise ambiguous or non-standard formats. Critical variables include piece weight to the nearest gram, thickness and flexibility, address placement, barcode quality, and presentation standards. For domestic flows, Royal Mail (Royal Mail Group Limited) and DSA (Downstream Access) partners offer preferential bands when your mail conforms precisely, while non-compliance triggers manual-handling surcharges and delays. Internationally, correct HS (Harmonized System) coding, EORI (Economic Operators Registration and Identification), and ICS2 (Import Control System 2) pre-advice protect you from re-ratings and border holds that devastate schedules.

Cliffe Enterprise Limited designs and tests physical dummies to validate machinability, calibrates paper and cover specifications to protect weight bands, and applies address-data cleansing to reduce undeliverables. For European deliveries, the company applies IOSS-ready VAT handling and bespoke international logistics to clear documentation and streamline injection into optimal hubs, helping to reduce transit volatility and limit per-copy cost variability. The result is higher deliverability, fewer returns, and more predictable postage that adds certainty to your campaign’s financial model. As a further safeguard, production and mailing are executed under ISO 9001 management arrangements and use FSC-audited paper sourcing to support quality and environmental control across the chain.

How Cliffe Enterprise Limited Neutralises Hidden Charges

Since 1991, Cliffe Enterprise Limited has delivered magazine printing with quality, cost-effective production, comprehensive mailing fulfilment, and expert postage optimisation across UK (United Kingdom) and overseas lanes. The company’s integrated model aligns plant schedules, materials purchasing, data processing, and postal routing so each decision is evaluated for its impact on total landed cost, not just the unit print price. By modelling weight scenarios, machinability outcomes, and international clearance requirements before quoting, Cliffe Enterprise Limited prevents last-minute upgrades, re-rates, and rework that typically inflate invoices after approval. That discipline is reinforced by decades of project data from thousands of titles, allowing benchmark-based advice tailored to your audience, frequency, and format.

- Magazine printing with calibrated paper and ink choices that protect postal weight bands while maintaining colour fidelity.

- Mailing fulfilment options: poly wrap, paper wrapping, or envelope enclosing, each costed against machine speed, material cost, and environmental obligations.

- Postal compliance and mail-out accuracy engineered to Royal Mail (Royal Mail Group Limited) and international standards to minimise surcharges.

- UK (United Kingdom) and overseas postage expertise with competitive rates, including IOSS-ready VAT handling and bespoke international logistics for Europe to reduce friction and cost.

- Worldwide magazine distribution for small to bulk orders with reliable service-level agreements and performance reporting.

- Consultative quoting with scenario analysis, test dummies, and data audits so your budget reflects reality, not wishful thinking.

Example outcome: a trade publisher mailing 28,000 copies cut total spend by 14 percent year-on-year by switching to paper wrap specified at a lighter caliper, tightening address hygiene with PAF (Postal Address File) and NCOA (National Change of Address) processing, and routing European copies via IOSS-ready routing and bespoke international logistics. The savings were driven by a maintained weight band, fewer undeliverables, and avoided international rework charges, confirming that careful engineering at specification stage beats late-stage cost firefighting.

Procurement Checklist: Lock Clarity Into Your Next Brief

Your brief is the best defence against hidden costs, because ambiguity invites optimistic pricing and later corrections. Use the checklist below to force precision at the moment the quote is assembled and to ensure your suppliers commit to the assumptions that truly drive cost. As you apply it, picture a simple diagram: at left sits your creative specification; in the middle, the manufacturing and data-prep nodes; and at right, postal networks domestic and international. Your goal is to make every handoff clean so the chain flows without exceptions.

- Define pagination, trim, spine thickness, and weight band with a signed-off dummy and weighed sample.

- Lock paper brand, gsm, caliper, and finish; specify allowed substitutions and price-adjustment rules.

- State colour profile targets and whether RGB (Red Green Blue) to CMYK (Cyan Magenta Yellow Key) conversion is included.

- List finishing and adhesives, including whether PUR (Polyurethane Reactive) binding is mandatory or optional.

- Set waste and overs as percentages with caps and define ownership of surplus copies.

- Provide data specification and request a per-thousand price for PAF (Postal Address File), NCOA (National Change of Address), and MPS (Mail Preference Service) processing.

- Choose wrapping: poly, paper, or envelopes, and ask for machine speed and yield assumptions.

- Request a machinability check and pre-approval of mailpiece design to lock rate bands.

- For Europe, confirm IOSS-ready routing, HS (Harmonized System) codes, and EORI (Economic Operators Registration and Identification) handling.

- Itemise project management, storage, split deliveries, and timed drops with unit charges.

- Ask for service levels and penalties for missed mail dates and undeliverable thresholds.

- Confirm ISO (International Organization for Standardization) 9001 compliance and FSC-audited paper sourcing for process and material control.

| Category | Fields to Specify | Supplier Response |

|---|---|---|

| Materials | Paper brand, gsm, caliper, cover finish, allowed substitutions | … |

| Prepress | Colour profile, preflight scope, correction caps, proof type | … |

| Finishing | Binding method, lamination, specials, trim tolerance | … |

| Data | PAF (Postal Address File), NCOA (National Change of Address), MPS (Mail Preference Service) pricing per thousand | … |

| Wrapping | Poly or paper, gauge, machine speed, EPR (Extended Producer Responsibility) note | … |

| Postage | Weight band, machinability test, Royal Mail (Royal Mail Group Limited) tariff, DSA (Downstream Access) options | … |

| International | IOSS-ready routing and customs support, HS (Harmonized System) codes, EORI (Economic Operators Registration and Identification) | … |

| Logistics | Split deliveries, storage, palletisation, timed drops, returns handling | … |

The most effective procurement teams do not merely gather prices; they standardise assumptions. That approach moves you from comparing apples and oranges to evaluating real efficiencies, such as faster machine speeds for paper wrapping or lower undeliverable rates from better data hygiene. Cliffe Enterprise Limited will walk you through these trade-offs with scenario models that show where a pound invested in specification design saves multiple pounds in postage, rework, and customer service. If you prefer, their specialists will also benchmark your current workflow against peers and flag latent risks before they become expensive fixes.

Case Examples: How Hidden Costs Disappear With the Right Partner

A consumer lifestyle publisher mailing 42,000 copies domestically and 6,000 to Europe faced unpredictable postage due to cover upgrades that nudged weight above a machinable threshold. By re-specifying the cover laminate, switching to paper wrap, and cleansing data via PAF (Postal Address File) and NCOA (National Change of Address), Cliffe Enterprise Limited restored the original weight band and cut undeliverables by 22 percent. IOSS-ready routing and bespoke logistics smoothed EU (European Union) entry, contributing to an estimated reduction in per-copy international costs while accelerating delivery by two days on average, according to internal performance logs.

Meanwhile, a B2B (Business to Business) publisher managing multiple regional versions absorbed frequent plate-change fees and storage charges. After consolidating versioning windows and agreeing a plate-change cap plus a transparent storage tariff, the team removed invoice surprises and saved 9 percent across two issues. These outcomes are not outliers; industry studies suggest that structured briefs, postal-compliant design, and early data checks routinely save 8 to 15 percent in total campaign costs, with higher gains when international mail is involved. The common thread is discipline from specification through mailing, reinforced by a partner that treats postal requirements as part of the design, not an afterthought.

All data and percentages above are indicative and will vary based on specification, market tariffs, and carrier policies. They nevertheless demonstrate how a transparent approach across printing, fulfilment, and postal routing unlocks predictable, lower total cost while sustaining brand quality and delivery performance.

Conclusion

Hidden charges vanish when your specification, data, and postal plan are engineered together and costed transparently.

Imagine the next 12 months with stable budgets, faster mail dates, and cleaner delivery reports because every decision is tested against real postal rules before ink hits paper.

Which of these line items will you insist on seeing next time you request quotes for magazine printing and mailing uk (United Kingdom)?

Eliminate Hidden Costs in Quotes for Magazine Printing and Mailing UK (United Kingdom) with Cliffe Enterprise Limited

Cliffe Enterprise Limited delivers quality, cost-effective magazine printing and postal-compliant mailing that reduces postage and improves deliverability for publishers, marketers, and production teams.