A brief explanation of the different binding options and

when best to use them

What is Saddle stitching?

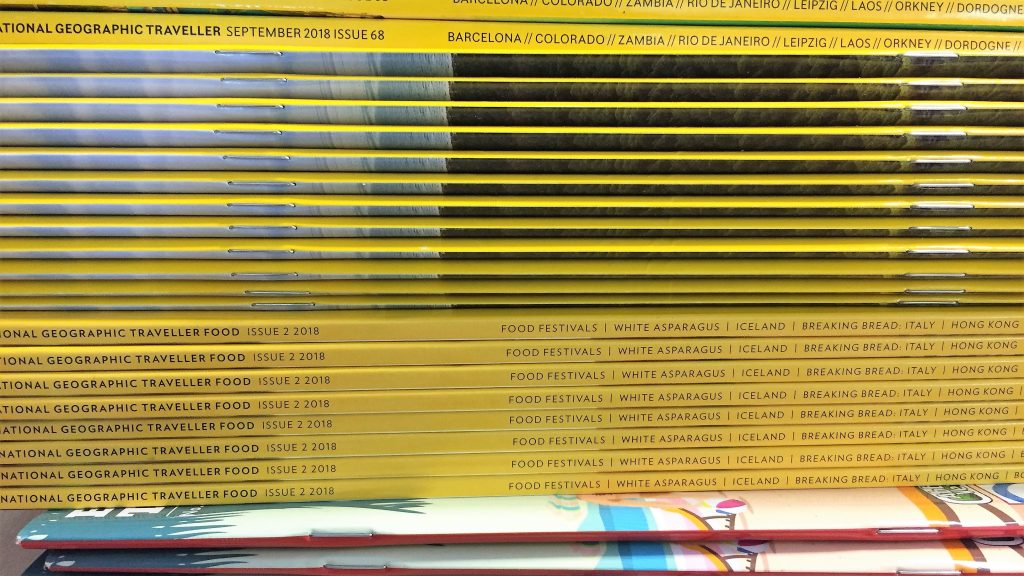

Saddle stitching is a binding method which places wire staples through paper, the name is thought to come from the ‘saddle’ apparatus which the collated paper is placed over when it is stapled together.

Saddle stitching is common for smaller products and pages must be in multiples of four because the paper is folded down the centre to create the centre seam (i.e. an A5 brochure would start life as an A4 sheet of paper folded and saddle stitched down the middle to create the A5 brochure). The smallest paged book that can be saddle stitched is an 8-page self-cover; where the cover uses the same paper as the interior pages, or 4 pages plus the cover; where the cover is a higher-grade paper to the interior pages. Typically books with no more than 64 pages can be saddle stitched although this is dependent on the paper thickness and staple size as you want a flat finish. For products with more than 64 pages perfect binding is an alternative binding.

Saddle stitching is used for brochures, catalogues, manuals, comic books and can be pocket size or larger page sized. It also lends itself to products using cross page or double page images. This binding method tends to be affordable and have a quick turnaround time. Products can also be hole punched for placing into ring binders and being a lighter weight bind it tends to keep mailing costs down.

What is Perfect Binding?

Perfect Binding is used for softback binding and as with PUR binding the pages and cover are glued together at the spine of the book. The spine can be printed on and the cover may be a heavier paper and be coated for a glossy and more durable covered finish. The cover and pages are then trimmed to give a perfect bound finish. The difference between Perfect binding and Polyurethane Reactive binding (PUR) is the glue, perfect binding typically uses Ethylene Vinyl Acetate (EVA), but PUR offers more durability than EVA so depending on the print project, PUR glue it is often the preferred choice.

Perfect binding is often used for paperback books as well as in magazine print, brochures, catalogues and company reports. It can be used for A6, A5 and A4 sized products with a range of paper grades and finishes. It can be used for high page count books (64+) but also lower production runs (around 150+ books) and produces a professional clean finish.

What is PUR?

Polyurethane Reactive binding (PUR) is a perfect binding technique used for binding softback books by gluing the pages and cover together at the spine of the book, and the cover and pages are trimmed to give a neat finish. PUR glue offers more durability than Ethylene Vinyl Acetate (EVA) glue and has great flexibility which leads to no cracking or ripping along the spine and the pages stay firmly in place even with heavy use. PUR also can withstand heat changes and will adhere a wide range of paper products including heavy weight paper and paper coatings and because of its strength, less glue is required which leads to a cleaner finish. PUR is also used for hardback book binding. Additional time should be given for a PUR printing project because it takes longer for the glue to set which ensures it durability

This guide is a ‘rule of thumb’ so please contact us to discuss your project requirements whether you are looking for brochure printing services or magazine printing or deciding which magazine printers to use we can advise you on what options will provide the quality and pricing you require. Feel free to call 01323 419701 or email simon@magazineprintingcompany.com

Feel free to look at our other blog posts on Brochure Printing, Fulfilment, Direct Mailing, Paper and Printing